3D Printer Installation and Maintenance

We support our customers' product development by combining 3D printers with other manufacturing methods.

We support our customers' product development by combining 3D printers with other manufacturing methods.

SOLIZE has the technical capabilities to handle everything from design and specification review to manufacturing, so we can solve the challenges of small-lot manufacturing, from prototyping to final product production.

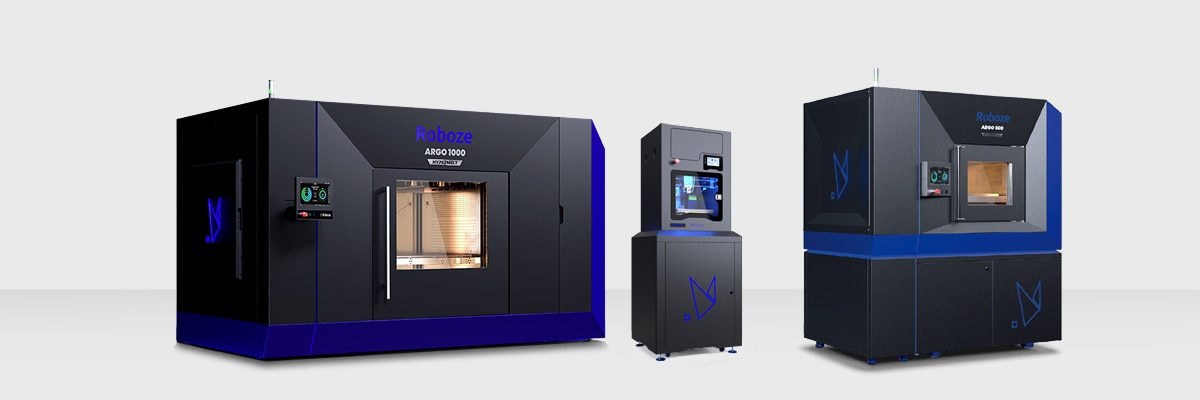

Since our founding in 1990, we have accumulated operational know-how as users and have continued to hone our 3D printing technology. When purchasing equipment, it is easy to focus on specs and functions, but finding a dealer that can provide reliable support and maintenance services are just as important factors as the performance of the equipment. SOLIZE will support our customers' 3D printing operations for the long term, from various angles, including operation, such as regular maintenance, emergency response, and technical consultations.

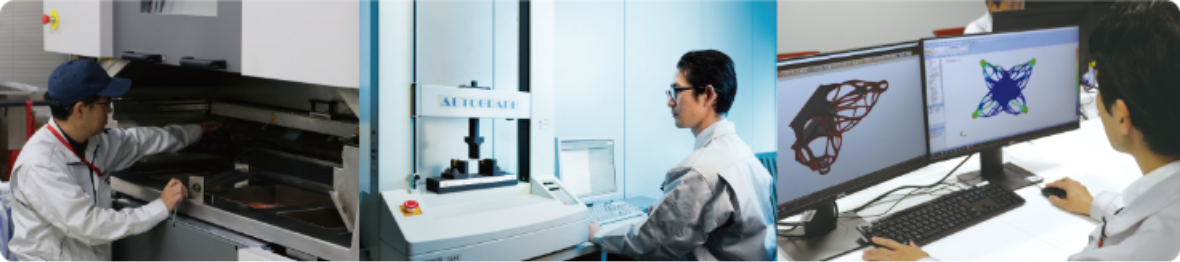

Implementation support based on many years of experience in handling 3D printers

Operation support by dedicated engineers

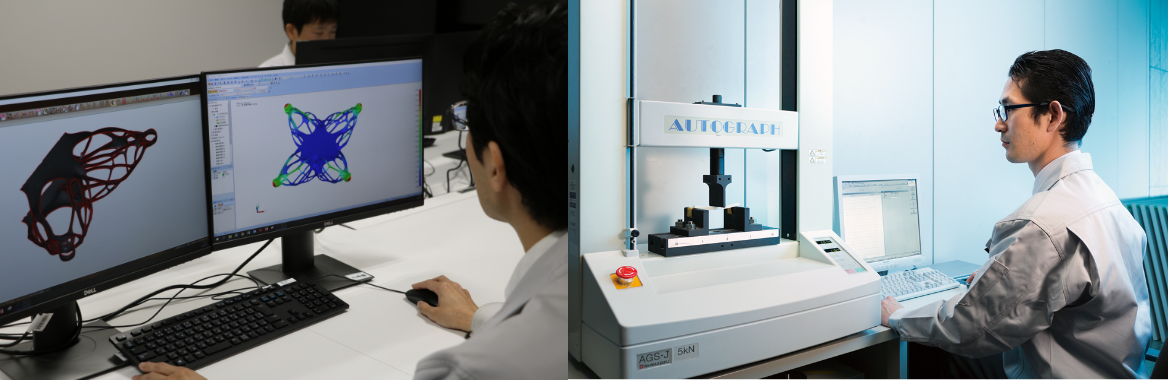

Product data design optimized for 3D printers

Post-processing for smooth surface and reduced labor

Introduced Figure 4 Standalone and used it to produce eyeglass frames for the company's own brand

[Effects after implementation]

Introduced Figure 4 Standalone and used it to manufacture the final product of our own development

[Effects after implementation]

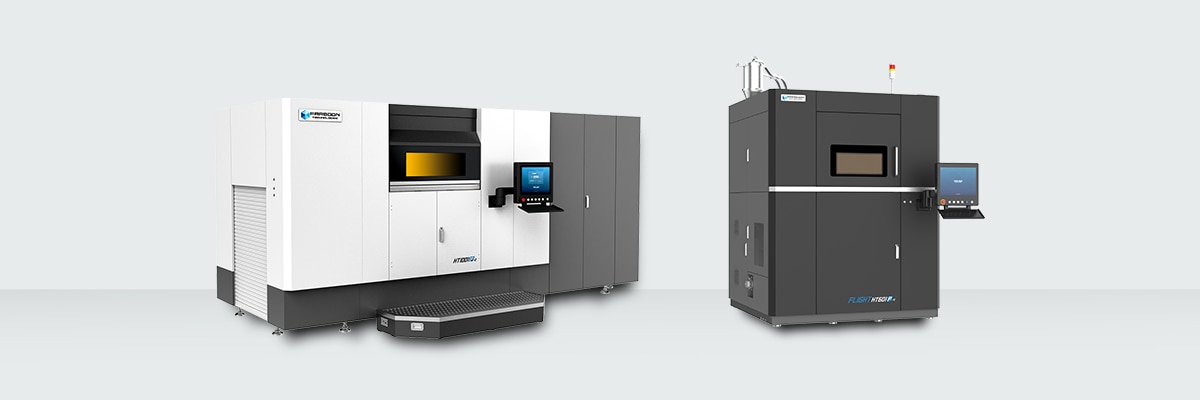

Introducing the HP Jet Fusion 5210 - Introducing the equipment with a view to applying it not only to prototypes but also to the final product -

Toyota Motor Corporation has traditionally used 3D printers to create prototypes.

When considering using 3D printers not only for prototyping but also for final product production, the HP Jet Fusion series was selected as a candidate, and Toyota has now introduced the HP Jet Fusion 5210.

In recent years, the productivity and material properties of industrial 3D printers have improved dramatically, and the range of applications for 3D printers has expanded beyond traditional prototyping, to include the use of jigs and tools and the production of final products, and their use has become more advanced. In particular, when producing final products with 3D printers, in addition to cost, productivity, and material properties, efforts in the design area (generative design) are also important, so in-depth verification before implementation is essential. SOLIZE has been using 3D printers for many years, so we are able to perform pre-implementation verification that would be difficult for other companies.

We support the creation of resin and metal prototypes through various methods, mainly using 3D printers, to the final product. We can also provide consultation on design and modeling.

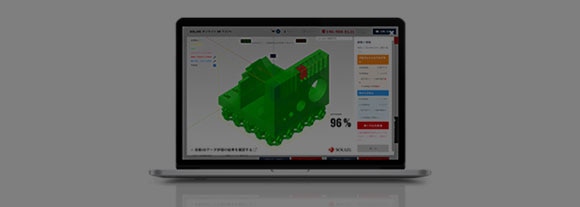

You can easily order 3D printing online. We can automatically estimate and evaluate data, and your order can be completed in as little as 3 minutes and shipped in as little as 3 days.

We pursue optimal solutions that take multiple factors into account through the development of modeling technologies that push the manufacturing limits of 3D printers and various analytical technologies, and we support our customers in their technological development to improve the value of their products.

Our unique digital engineering solves product development issues, including QCD improvements.

As well as creating high-quality 3D models, we are also able to take on many aspects of the design process, including coming up with styling concepts and proposing styling shapes.

We handle design work in product development in a wide range of work, from interior and exterior parts for automobiles, which require a high level of quality, to the design of manufacturing machines for production lines.

We combine various analysis technologies and propose optimal solutions from a huge amount of analysis results. We provide a proposal-based analysis service that analyzes the underlying causes of the customer's issues and finds analysis conditions and countermeasures.

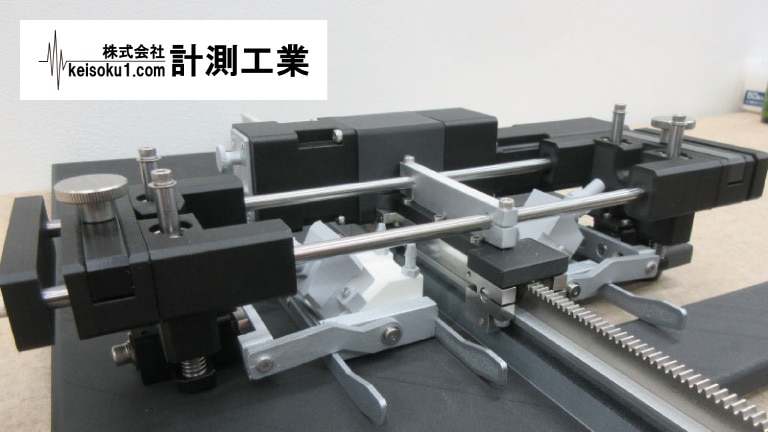

We support our customers' product development by combining various manufacturing methods, centered around 3D printers, to produce prototypes, mockups, visualization models, test models, jigs, and more.

Using our many years of 3D printer operation know-how and the latest 3D printers suited to the final product, we support the selection of applicable parts, material evaluation, redesign, production preparation, final product production, and expansion of applicable parts.

We will improve manufacturing productivity by making the most of 3D digital technology, including CAD. We will improve quality in design and manufacturing, eliminate dependency on humans, and shorten lead times.

We will maximize the use of XR technology to improve manufacturing productivity. We will provide new sensations and experiences that only XR technology can provide, primarily at production sites.

We will maximize the use of AI technology to improve manufacturing productivity. By introducing cutting-edge technology into manufacturing, we will be able to tackle difficult problems that have not been solved before.

We will assist you in solving any issues related to digitalization, including calculating carbon footprints and quantifying and improving the environmental impact of your products.

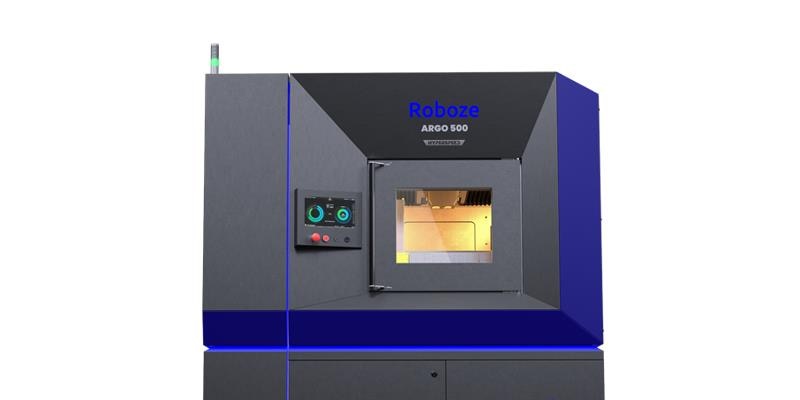

We specialize in high-performance industrial 3D printers, and will provide long-term support for our customers' 3D printing operations, including not only sales but also operation.