Digital Engineering Support

Resolving QCD Issues with Digital Engineering

Resolving QCD Issues with Digital Engineering

QCD improvement measures are not leading to results

The quality of the work varies depending on the engineer.

There is a lot of rework, and it takes time to review and correct things.

I'm always pressed for deadlines

Simply introducing and using digital tools will not lead to results

In order to solve all QCD issues at once, the use of digital engineering is essential.

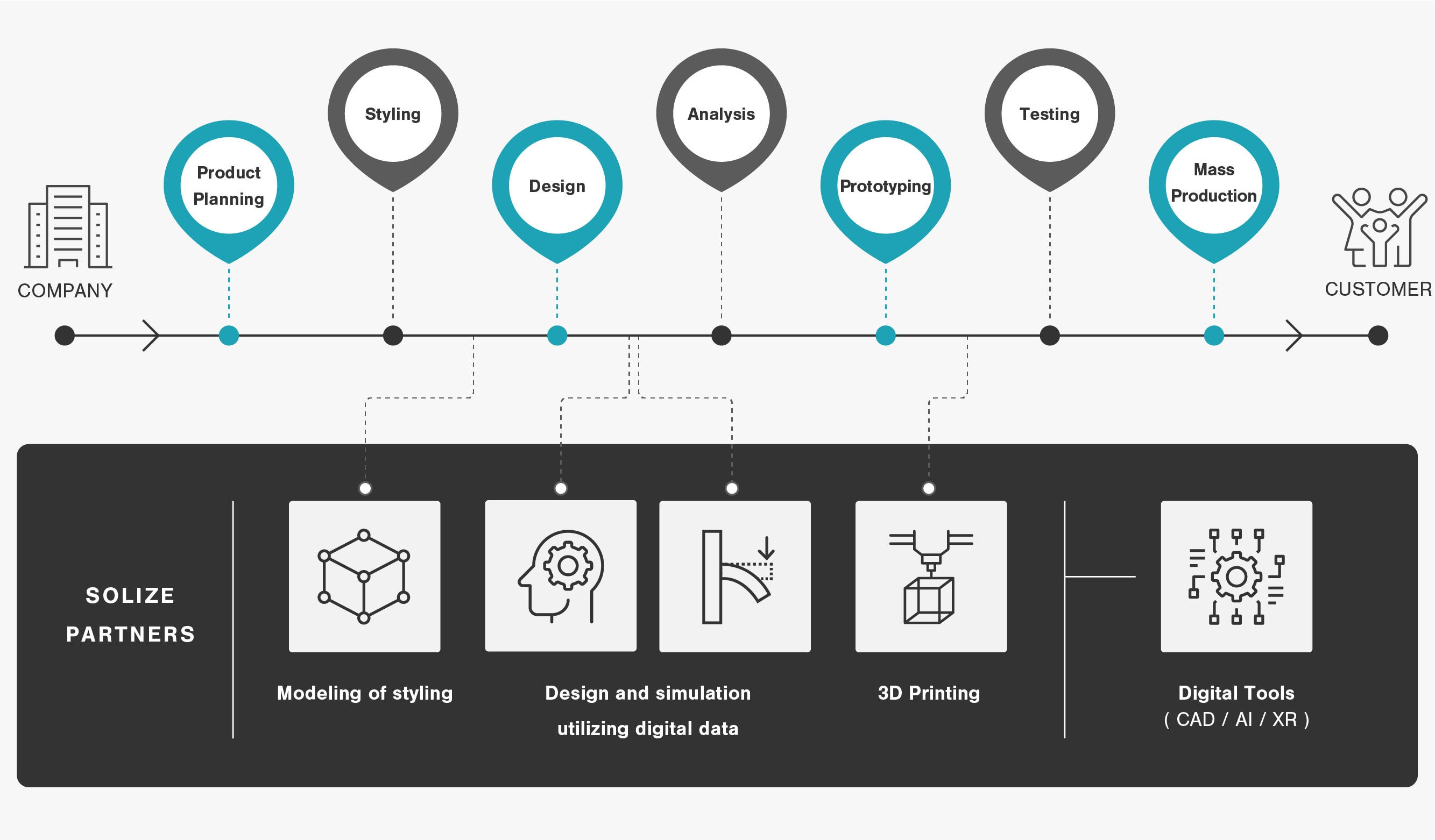

SOLIZE PARTNERS is the first company in Japan to develop a manufacturing business that utilizes digital technologies, including 3D printers. We leverage our experience to provide high-quality manufacturing with our unique digital solutions.

We are able to handle many areas of the engineering chain in-house, from design modeling to small-lot production. By utilizing our knowledge and experience in a wide range of specialized fields, we can propose solutions that will not fail even as the development phase progresses. And we can implement them quickly using our own digital technology.

SOLIZE PARTNERS is guided by the principle of being the best partner for our customers, and we take on the challenges our customers face as our own, working to resolve them. You can count on SOLIZE PARTNERS to shape the future together with our customers, using our technology and passion.

Technology x Technology = Creating Synergy

SOLIZE PARTNERS' digital engineering is not only effective in improving QCD, but also in understanding and shaping the unarticulated needs of our customers. By combining our wide range of technical fields, we can create new value.

We cooperated in the design and production of piping for wind tunnel testing models, reducing the lead time to wind tunnel testing by 1/4 and the cost by 1/3

The team learned about 3D printed wind tunnel models at an academic conference, and in order to solve their problem, they made use of SOLIZE's 3D printed prototype production service, which has experience in producing models for wind tunnel experiments at Sensoji Temple and can also design them.

Development of 3D digital tools that improved cockpit product quality and reduced labor costs

SOLIZE's 3D printed products have been adopted for mockups to be displayed at large-scale exhibitions such as "JAPAN MOBILITY SHOW 2023" and "International Logistics Exhibition 2024."

Supporting the development of 3D-MBD utilization processes that revolutionize the communication of design and manufacturing information in concurrent activities

To solve problems such as "difficulty in conveying part shapes" and "lack of promotion of use of 3D models" caused by information transmission mainly based on 2D drawings, we established methods and processes that can accurately convey design intent using 3D-MBD and efficiently utilize it in the manufacturing process, reducing the number of work hours in the manufacturing process by 80% and reducing the number of inquiries from partners by reducing rework.

Standardization along with the design site x CAD template construction support reduces drawing man-hours and achieves zero quality defects

Standardization along with the design site x CAD template construction support reduces drawing man-hours and eliminates quality defects. In response to increasingly sophisticated and diverse market needs, we have made it our mission to increase efficiency through design standardization in order to reduce man-hours, and have begun providing CAD template construction support as a measure to promote and comply with design standardization.

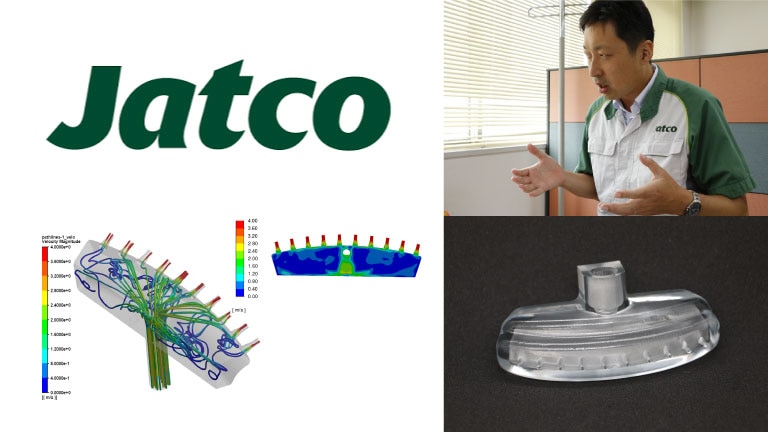

Cooperating to create nozzles to prevent chip clogging in machining centers through analysis, design and 3D printing

In order to ensure that the coolant reaches the desired location, we commissioned SOLIZE to design a nozzle using analytical technology and manufacture the nozzle using a 3D printer, reducing minor stops and breakdowns and improving production efficiency.

Improving the quality of masking jigs used on mass production paint lines with 3D printing technology

As a permanent solution to the paint defects, we adopted SOLIZE's 3D printer-utilizing design (Design for Additive Manufacturing: DfAM) and AM technology implementation support service.

We have a wide range of contract types to choose from depending on your needs. Please feel free to contact us if you have any other requests.

A dispatch contract is a contractual form in which engineers employed by our company are dispatched to the client's workplace. The engineers perform their work under the client's command and control.

A contract for work is a type of contract aimed at completing and delivering a specific task or deliverable. We carry out the work based on the requirements agreed upon at the time of the contract and deliver the deliverables responsibly.

A quasi-entrustment contract is a contract form whose purpose is the actual execution of work, such as consideration and response. Even for work where it is difficult to clarify the requirements for the deliverables at the time of signing the contract, a lump sum of man-hours can be secured.

01

Sales representatives for each service are equipped with technical knowledge and will respond to your inquiries.

02

We will ask you about your concerns, such as the nature of your business and the skills you require. We can also discuss technical details after signing an NDA.

03

We will propose development support that matches our customers' needs, along with the contract type.

04

You will decide on the type of contract (dispatch, contract, or quasi-entrustment) and we will conclude a contract based on compliance.

05

Dispatch contract

On the start date, a sales representative will accompany the engineer to assist with smooth implementation.

Quasi-agency contract/contract contract

The sales representative will begin work promptly after the contract is signed.

Our unique digital engineering solves product development issues, including QCD improvements.

As well as creating high-quality 3D models, we are also able to take on many aspects of the design process, including coming up with styling concepts and proposing styling shapes.

We handle design work in product development in a wide range of work, from interior and exterior parts for automobiles, which require a high level of quality, to the design of manufacturing machines for production lines.

We combine various analysis technologies and propose optimal solutions from a huge amount of analysis results. We provide a proposal-based analysis service that analyzes the underlying causes of the customer's issues and finds analysis conditions and countermeasures.

We support our customers' product development by combining various manufacturing methods, centered around 3D printers, to produce prototypes, mockups, visualization models, test models, jigs, and more.

Using our many years of 3D printer operation know-how and the latest 3D printers suited to the final product, we support the selection of applicable parts, material evaluation, redesign, production preparation, final product production, and expansion of applicable parts.

We will improve manufacturing productivity by making the most of 3D digital technology, including CAD. We will improve quality in design and manufacturing, eliminate dependency on humans, and shorten lead times.

We will maximize the use of XR technology to improve manufacturing productivity. We will provide new sensations and experiences that only XR technology can provide, primarily at production sites.

We will maximize the use of AI technology to improve manufacturing productivity. By introducing cutting-edge technology into manufacturing, we will be able to tackle difficult problems that have not been solved before.

We will assist you in solving any issues related to digitalization, including calculating carbon footprints and quantifying and improving the environmental impact of your products.

We specialize in high-performance industrial 3D printers, and will provide long-term support for our customers' 3D printing operations, including not only sales but also operation.