3D Printed Parts Manufacturing

We support the creation of everything from resin and metal prototypes to final products using a variety of methods, primarily 3D printers. We can also provide consultation on design and modeling.

We support the creation of everything from resin and metal prototypes to final products using a variety of methods, primarily 3D printers. We can also provide consultation on design and modeling.

Want to produce prototypes with a short lead time and low cost

Looking for a company that can manufacture final products using 3D printers

Want to proceed while consulting on technical details because specifications are not yet finalized

Want to collaborate on the development of 3D printer component technologies

SOLIZE will help you solve your problems with high technical capabilities and flexible response, from prototyping to final product production.

SOLIZE was the first 3D printing service bureau in Japan to introduce 3D printers domestically and has been engaged in additive manufacturing for more than 35 years. We have served over 2,000 customers, including major domestic automotive manufacturers.

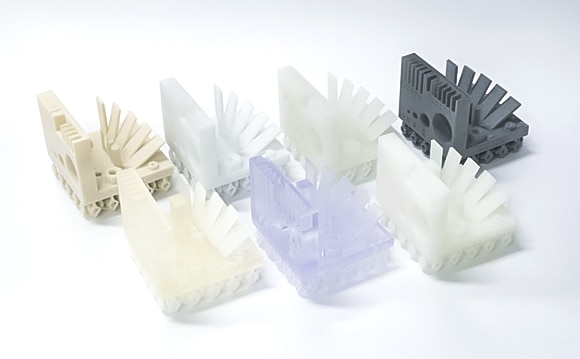

We own high-quality, high-precision high-end 3D printers from 3D Systems and HP. We select the most suitable equipment depending on the application and always propose solutions that optimize quality, cost, and delivery (QCD) for our customers. We manufacture over 80,000 parts annually.

Our engineers come from diverse fields such as automotive parts, home appliances, consumer goods, and toys. We confirm the customer's ultimate goals and create designs and 3D data tailored to the application. We also offer design proposals considering the characteristics of 3D printers (DfAM) and topology optimization aimed at weight reduction.

Easily place 3D print orders online. Automated quoting and data evaluation enable order completion in as little as 3 minutes, with shipping available in as little as 3 days.

We provide end-to-end support from hearing your needs and reviewing specifications, to data creation, inspection, and delivery. Using 3D printers and various other manufacturing methods, we offer a wide range of services tailored to your schedule and budget.

Leveraging our extensive experience with 3D printers and the latest machines suitable for final products, we support everything from component selection, material evaluation, redesign, production preparation, final product manufacturing, to expanding applicable parts.

We assist your technology development aimed at enhancing product value by expanding the manufacturing limits of 3D printing through "development of fabrication technologies" and pursuing "optimal solutions considering multiple factors" using various analysis techniques.

SOLIZE owns 42 3D printers across six different additive manufacturing methods, making it one of the largest fleets in Japan.

In addition to 3D printing, we also support various manufacturing processes such as machining, sheet metal processing, casting, mold prototyping, and more. We provide proposals tailored to the intended use, budget, and delivery schedule of your product.

We handle a wide range of materials including plastics (from general resin materials to high-performance engineering plastics like PEEK), rubber materials, and metals such as aluminum, stainless steel, and magnesium. For 3D printing, we offer a standard lineup of over 20 different materials.

If you require materials not listed in our supported materials catalog, please feel free to contact us.

1/1 scale mockups for product PR produced in a short period of time

SOLIZE cooperated with Sanden Corporation in the production of a large-scale mockup. In preparation for their exhibit at CES 2025, one of the world's largest consumer electronics and IT trade shows, SOLIZE made multiple proposals even without detailed specifications, and quickly completed a mockup of an automobile that would catch the eye even in an exhibition hall dominated by consumer electronics.

A mockup of the stationary energy storage system "MEGALORE" was created using a 3D printer

SOLIZE's 3D printed products have been adopted for mockups to be displayed at large-scale exhibitions such as "JAPAN MOBILITY SHOW 2023" and "International Logistics Exhibition 2024."

We cooperated in the design and production of piping for wind tunnel testing models, reducing the lead time to wind tunnel testing by 1/4 and the cost by 1/3

The team learned about 3D printed wind tunnel models at an academic conference, and in order to solve their problem, they made use of SOLIZE's 3D printed prototype production service, which has experience in producing models for wind tunnel experiments at Sensoji Temple and can also design them.

[First case in Japan] Lexus LC500 genuine optional part "Oil cooler duct" manufactured with 3D printer

SOLIZE's HP Jet Fusion 3D printed product has been adopted for the duct of the automatic transmission (AT) oil cooler, which will be installed as an option on the Lexus LC500 from the 2024 model year. This is the first time in Japan that a 3D printed product has been adopted for a genuine optional part by an automobile manufacturer.

SOLIZE's 3D printing final product production adopted for BNR32 defroster grill

SOLIZE has achieved the design and manufacture of replacement parts using 3D printing for the first time in the "NISMO Heritage" initiative by Nissan Motor Co., Ltd. in 2021. This time, as the second installment of the "NISMO Heritage Parts," SOLIZE has produced a 3D printed final product to reproduce the defroster grille to be installed on the dashboard.

High-end headphones are made with a 3D printer, reducing weight and reducing costs

Iida Piano Co., Ltd. has released the new KuraDa brand headphones "KD-Q1" for the first time in six years. SOLIZE's 3D printing final product production service was used to produce most of the body, such as the housing and arms.

JAXA and SOLIZE jointly develop metal 3D printed loop heat pipe ~World's first thermal control device made by integrally molding two different types of porous bodies~

JAXA is a national research and development agency that conducts research and development of domestic rockets, artificial satellites, aircraft, etc. JAXA and SOLIZE are jointly developing the porous body, the heart of the next-generation device "loop heat pipe" that handles the thermal management of satellites and probes in space, using metal 3D printing technology.

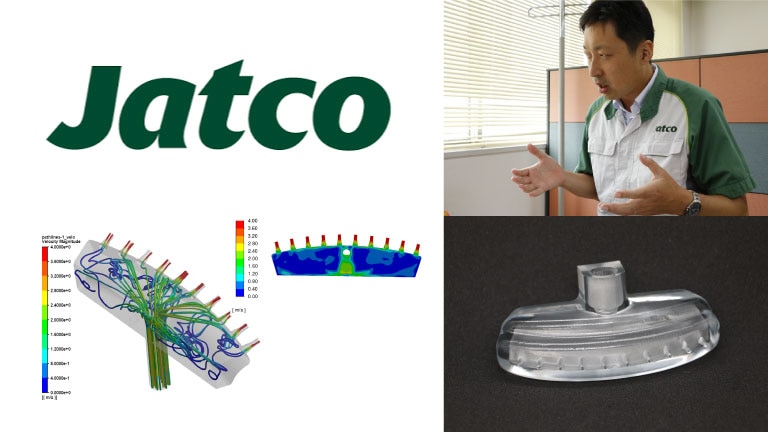

Cooperating to create nozzles to prevent chip clogging in machining centers through analysis, design and 3D printing

In order to ensure that the coolant reaches the desired location, we commissioned SOLIZE to design a nozzle using analytical technology and manufacture the nozzle using a 3D printer, reducing minor stops and breakdowns and improving production efficiency.

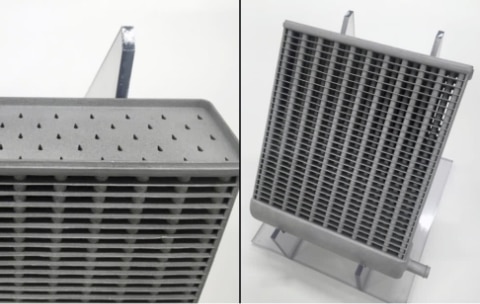

Improving the quality of masking jigs used on mass production paint lines with 3D printing technology

As a permanent solution to the paint defects, we adopted SOLIZE's 3D printer-utilizing design (Design for Additive Manufacturing: DfAM) and AM technology implementation support service.

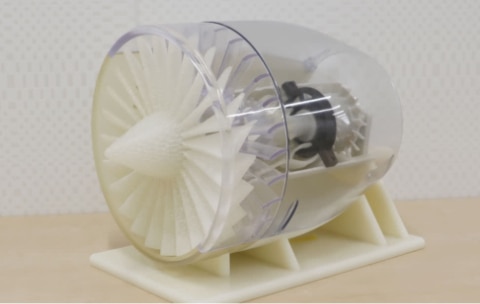

Material: AlSi12

Purpose: Performance evaluation model

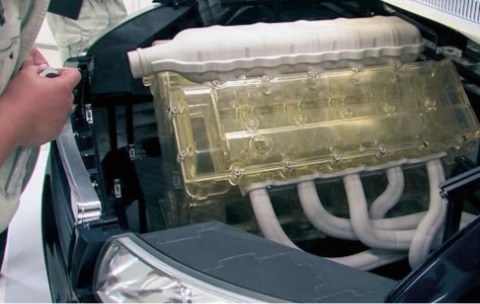

Material: Duraform® GF + heat-resistant resin

Delivery time: 1 week or more

Secondary processing: Insert bonding

By studying the engine assembly process in advance, the production line can be started up early. Also, by using heat-resistant transparent materials, visualization testing is possible.

Q.

A.

There will be an additional charge, but we can handle everything from creating the data.

Q.

A.

Although it depends on the shape and size, we can deliver as soon as the next day. Please contact us first.

Q.

A.

We can also handle STL and OBJ formats for 3D printer output, as well as intermediate files (.stp) and CAD data such as CATIA.

Our unique digital engineering solves product development issues, including QCD improvements.

As well as creating high-quality 3D models, we are also able to take on many aspects of the design process, including coming up with styling concepts and proposing styling shapes.

We handle design work in product development in a wide range of work, from interior and exterior parts for automobiles, which require a high level of quality, to the design of manufacturing machines for production lines.

We combine various analysis technologies and propose optimal solutions from a huge amount of analysis results. We provide a proposal-based analysis service that analyzes the underlying causes of the customer's issues and finds analysis conditions and countermeasures.

We support our customers' product development by combining various manufacturing methods, centered around 3D printers, to produce prototypes, mockups, visualization models, test models, jigs, and more.

Using our many years of 3D printer operation know-how and the latest 3D printers suited to the final product, we support the selection of applicable parts, material evaluation, redesign, production preparation, final product production, and expansion of applicable parts.

We will improve manufacturing productivity by making the most of 3D digital technology, including CAD. We will improve quality in design and manufacturing, eliminate dependency on humans, and shorten lead times.

We will maximize the use of XR technology to improve manufacturing productivity. We will provide new sensations and experiences that only XR technology can provide, primarily at production sites.

We will maximize the use of AI technology to improve manufacturing productivity. By introducing cutting-edge technology into manufacturing, we will be able to tackle difficult problems that have not been solved before.

We will assist you in solving any issues related to digitalization, including calculating carbon footprints and quantifying and improving the environmental impact of your products.

We specialize in high-performance industrial 3D printers, and will provide long-term support for our customers' 3D printing operations, including not only sales but also operation.